Railway programs stand being a backbone of infrastructure, evolving steadily to fulfill the growing calls for for effectiveness and sustainability. Amongst the technologies driving this evolution, hydraulic pumps Engage in a pivotal part in shaping the efficiency and operational effectiveness of railway servicing. Hydraulic systems, significantly higher-tension hydraulic pumps, have remodeled track routine maintenance, enabling speedier repairs, enhanced precision, and minimized downtime. This website explores how hydraulic pumps are revolutionizing railway techniques, focusing on superior-tension pump usage, picking out the best tools, along with the evolving role of Power effectiveness in hydraulic solutions.

Table of contents:

How substantial-Pressure Hydraulic Pumps strengthen routine maintenance velocity

picking the ideal Hydraulic Pump for Specialized Railway devices

Energy-effective Hydraulic Pump remedies for monitor Maintenance

How superior-force Hydraulic Pumps make improvements to upkeep velocity

Hydraulic programs, particularly significant-force hydraulic pumps, improve effectiveness and speed up routine maintenance in railway devices. These website pumps provide the facility to execute intense duties like observe lifting, alignment, and stabilization with unparalleled precision. customized-made by hydraulic pump suppliers, these pumps integrate seamlessly into railway routine maintenance devices, offering high drive without compromising on Handle. Their capability to operate less than severe ailments while reducing downtime guarantees clean railway functions, very important for very long-term infrastructure sustainability. Additionally, Superior hydraulic answers include things like eco-pleasant hydraulic fluids, decreasing each Electricity use and environmental hurt, aligning Together with the rising worldwide shift towards greener industrial methods. firms like QM observe underline these developments, providing solutions made for seamless integration and trustworthiness, emphasizing not only performance but will also environmental sustainability of their application.

Selecting the correct Hydraulic Pump for Specialized Railway Machines

deciding on the appropriate hydraulic pump is critical for specialized railway apps. the method entails matching the hydraulics' ability Along with the numerous prerequisites of railway gear, from tamping devices to rail grinding devices. Hydraulic pump producers such as QM Track play a pivotal position in supporting industries by offering customizable alternatives personalized to distinctive operational requirements. These brands center on generating pumps that emphasize toughness and strong construction, traits which might be critical for managing the troubles of demanding and infrequently harsh environments. with the utilization of advanced resources and innovative designs, these pumps are constructed to resist rigorous pressures and extended-time period put on. Precision engineering makes certain that the pumps operate seamlessly, providing trustworthy general performance in necessary servicing tools. This dependability is very important, especially in industries for instance railway solutions, where uninterrupted operation is important for protection, effectiveness, and minimizing downtime. By offering higher-quality, trusted hydraulic pumps, companies like QM monitor add appreciably to the smooth operation of vital infrastructure.On top of that, The supply of custom made hydraulic methods aids in Assembly particular person task demands, enabling operators to enhance performance and performance immediately aligned with challenge requirements. reputable pumps make sure minimized downtime over the board, causing enhanced efficiency and decreased operational expenses for railway entities.

Power-Efficient Hydraulic Pump alternatives for observe upkeep

Power-efficient hydraulic pump techniques are reshaping railway functions by minimizing Power intake and operational prices. These techniques integrate advanced parts personalized for Power price savings, aligned with world environmental sustainability aims. for instance, eco-friendly hydraulic devices from QM monitor integrate specially engineered fluids and higher-performance factors built to curtail emissions and raise General performance. The adoption of such impressive hydraulic alternatives in railway techniques not simply can help businesses enhance assets and also underscores their motivation to sustainability. In addition, Power-efficient hydraulic types lower use and tear, prolonging the lifespan of important equipment and streamlining monitor servicing processes. Sophisticated versions even attribute intelligent Handle techniques that dynamically adapt to variable working disorders, ensuring exceptional functionality though conserving Electricity. By buying energy-efficient options, railway operators maximize their return on investment decision whilst contributing to broader world environmental goals.

Hydraulic pumps signify a critical component in advancing railway effectiveness and sustainability. With all the escalating demand for seamless functions and lessened environmental influence, these methods stand as crucial applications, enabling faster monitor upkeep, Increased trustworthiness, and eco-acutely aware methods. From large-stress pumps to energy-economical models, their integration within enterprises displays innovation and strategic planning by hydraulic pump brands. By leveraging reducing-edge hydraulic methods, enterprises have the chance to streamline routine maintenance, minimize downtime, and extend the lifecycle of railway equipment, positioning by themselves properly in a fast-evolving marketplace. For specialists and gurus in railway programs, the focus ought to stay on adopting this sort of ahead-thinking alternatives to satisfy latest worries and put together for foreseeable future calls for.

Jake Lloyd Then & Now!

Jake Lloyd Then & Now! Rider Strong Then & Now!

Rider Strong Then & Now! Jason J. Richter Then & Now!

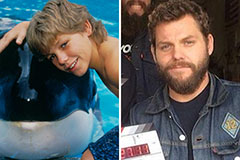

Jason J. Richter Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now!